维修和翻新

帮助波士顿地铁对开裂的隧道进行防水处理,使其重新恢复干燥

马萨诸塞湾交通局地铁系统是美国历史最悠久的地铁系统。这就意味着这个老旧基础设施的上上下下需要大量维修工作。

我们最近参与了沿红线的戴维斯车站东部及西部隧道的维修项目。隧道顶部和墙壁的裂缝导致渗水。结果使第三条铁轨附近出现积水现象。无需多说,水和600伏特的电流确实是糟糕的组合。

在顶部天花板和墙壁裂缝位置,承包商采用了DE NEEF® 迪尼夫® nbspFlex SLV PURe™解决方案杜绝渗水问题。结果就是干燥的隧道,搭乘红线的乘客拥有安全的环境和愉快的乘车体验。

项目简介

如何修复出故障的隧道挖掘机?需要非常小心。

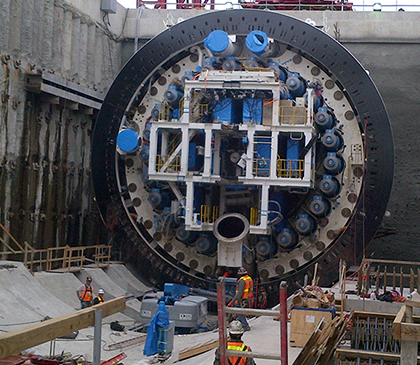

The largest tunnel bore machine (TBM) was used in the Alaskan Viaduct Replacement project in Seattle. This job included boring a two-mile-long highway tunnel under downtown Seattle. Due to unforeseen conditions, the machine, called Big Bertha became stuck and over time the cutter head was damaged. So much so that workers had to remove and extract the cutter head. To do that, though, they had to stabilize and waterproof the soil surrounding the shield without "gluing" the shield in place. We helped develop a plan to inject DE NEEF® acrylate around the perimeter of the tunnel between the last tunnel segments and the rear of the TBM shield. Five hundred gallon batches of injection material was mixed and pumped at a rate of eight minutes per gallon into each of the injection locations. Four weeks later, the project came to a successful end. And the TBM was operational again.