PV® 100

A unique multi-layer composite pre-applied waterproofing membrane that bonds integrally to poured concrete

Product Description

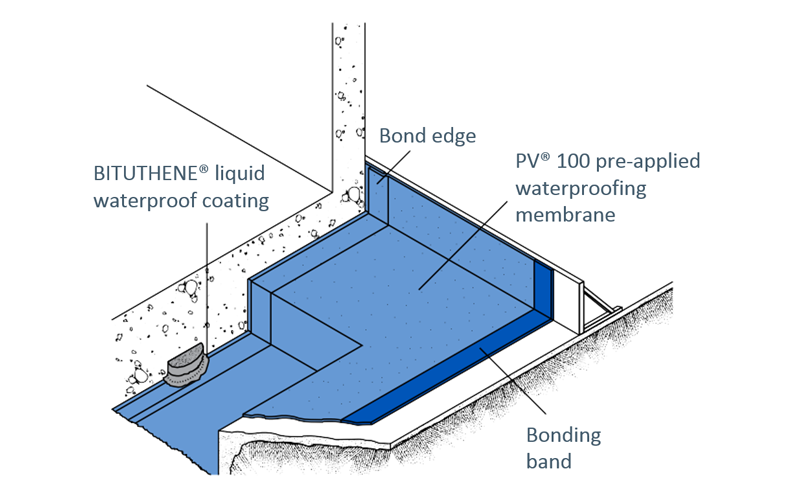

PV® 100 pre-applied waterproofing membrane is a multi-layer composite waterproofing material with superior performance, including a layer of high-performance PE film, self-adhesive polymer layer and a unique particulate layer.

PV® 100 pre-applied waterproofing membrane can be applied on a smooth level concrete surface, qualified compacted sand-stone cushion, or used as the waterproof layer of vertical surfaces of temporary and adjacent structures. After pouring concrete directly on to the paved PV® 100 preapplied waterproofing membrane, the poured concrete will bond fully and permanently with PV® 100 pre-applied waterproofing membrane.

PV® 100 pre-applied waterproofing membrane protects concrete foundation against aggressive ground contaminants and is suitable for water and vapour-proofing for all basement grades.

PV® 100 pre-applied waterproofing membrane is supplied at a width of 1.0m. Pour concrete after the steel bars are tied up. Please contact your local GCP representative for application details.

Product Advantages

- Forms permanent bond to concrete poured against it.

- Not affected by the displacement of the basal layer/ ground settlement beneath slabs

- Membrane is self-protecting. It can be trafficked immediately after application and does not require the use of protective layer

- Simple and quick to install, requiring no priming or fillets

- Unaffected by wet conditions

- Fully-adhered watertight laps and detailing

- Excellent bonding even under long-term water immersion

Installation

Substrate Preparation

All Surfaces

It is essential to create a sound and solid substrate to eliminate movement during the concrete pour. Substrates must be regular and smooth with no gaps or voids greater than 12mm.

HYDRODUCT® drainage composites can provide the membrane with a good surface and facilitate underground structural drainage.

Horizontal Blinding

The substrate must be free of loose aggregate and sharp protrusions. Avoid curved or rounded substrates. The surface does not need to be dry, but standing water must be removed.

Vertical Sheet Piling

Use concrete, or 19mm thick plywood, insulation or other approved facing to sheet piling to provide support for the membrane. Board systems such as timber lagging must be close butted to provide support and not more than 12mm out of alignment.

Membrane Installation

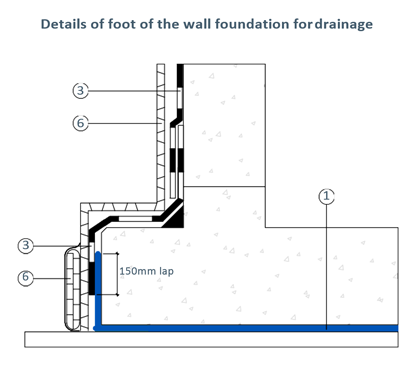

When placing PV® 100 pre-applied waterproofing membrane, overlap the bonding edge. Use a steel roller to press the bonding edge firmly to ensure complete bonding and to achieve continuity. PV® 100 pre-applied waterproofing membrane can be applied at -4ºC and above. When installing PV® 100 waterproofing membrane in cold or marginal weather, the bonding edge may be heated appropriately with hot air gun or similar devices to remove moisture in order to enhance bonding.

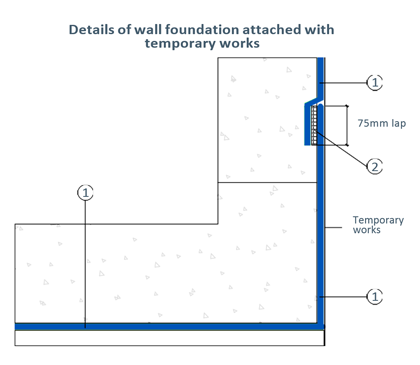

Place the membrane PE film side to the substrate with particulate layer side up, facing the concrete pour. End laps should be staggered to avoid build up of layers. Accurately position succeeding sheets to overlap the previous sheet 75mm along the marked selvedge. Ensure the underside of the succeeding sheet is clean, dry and free from contamination before attempting to overlap. Ensure a continuous bond is achieved without creases and roll firmly with a heavy roller. Any initial tack will quickly disappear.

Roll Ends and Cut Edges

Overlap all roll ends and cut edges by a minimum 75mm and ensure the area is clean and free from contamination, wiping with a damp cloth if necessary.

Remove all floating particulates from the surface of the PV® 100 pre-applied waterproofing membrane by brush. Brush a thin layer of Contact Adhesive Primer to cover the particulates on overlap area. When primer dries, apply PV® 100 Tape or Grace RA Double-sided Tape or Preprufe Tape by peeling off release paper and fix the adhesive side on substrate. Roll firmly to ensure complete adhesion without creases or voids. Peel off the other

layer of release paper and apply another piece of PV® 100 to the adhesive tape. Roll firmly to ensure complete adhesion.

Pouring of Concrete

The concrete must be poured within 21 days of application of the membrane. During pouring, take care when vibrating concrete to avoid damaging the waterproofing materials.

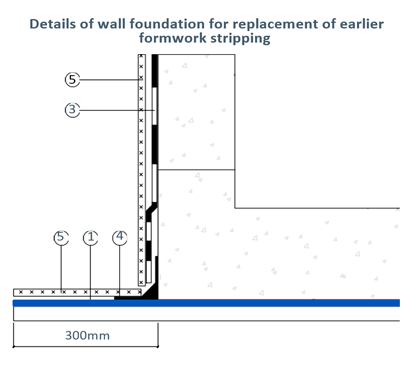

Formwork Removal

PV® 100 pre-applied waterproofing membrane can be applied to removable formwork, such as slab perimeters, elevator and lift pits, etc. Once the concrete is poured the formwork must remain in place until the concrete has gained sufficient compressive strength to develop the surface bond. PV® 100 pre-applied waterproofing membrane is not recommended for conventional twin-sided wall forming systems.

Physical Properties

| Standard | GB/T 23457 - 2017 |

| Property | Typical Value |

| Colour | White |

| Thickness | 1.2, 1.5mm |

| Tensile Strength, Film | ≥ 600N / 50mm |

| Elongation (Film) | ≥ 400% |

| Nail Tear Resistance | ≥ 400N |

| Low Temperature Bending | Film only, -35ºC |

| Low Temperature Flexibility | -25ºC, No crack |

| Water Migration Resistance | 0.8Mpa/35mm, 4h No water migration |

| Peel Adhesion to Concrete, No Treatment | ≥ 1.5N / mm |

| Peel Adhesion to Concrete, Surface Contaminatio by Sediment | ≥ 1.0N / mm |

| Peel Adhesion to Concrete, After Membrane Water Immersion | ≥1.0N/mm |

| Peel Adhesion to Concrete, After Heat Aging | ≥ 1.0N / mm |

| Peel Adhesion to Concrete, After UV Exposure | ≥ 1.0N / mm |

| Peel Adhesion to Concrete, After Water Immersion | ≥ 1.0N / mm |

| Heat Resistance 80ºC, 2h | No displacement, sagging, dripping |

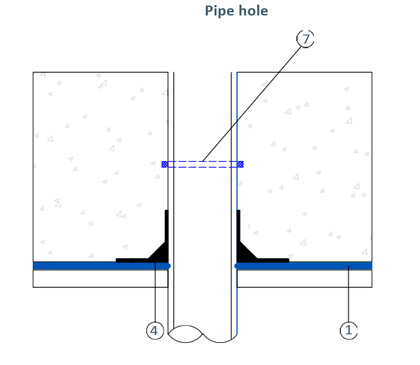

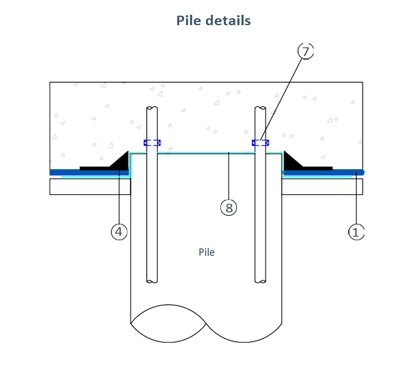

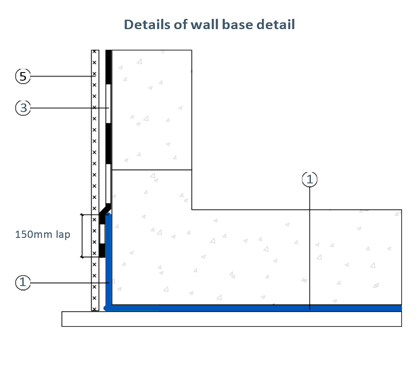

① PV® Pre-Applied Waterproofing Membrane

② PV® 100 Tape, PREPRUFE® Tape

③ Self-Adhesive Water Membrane or Grace RA Double-Sided Tape with Contact Adhesive Primer

④ BITUTHENE® Liquid Membrane

⑤ Protection Board

⑥ HYDRODUCT® Drainage Sheet

⑦ SWELLSEAL® Mastic

⑧ BETEC® M-5 Crystallisation

Supply

Health and Safety

Refer to relevant Safety Data Sheet. Complete rolls should be handled by a minimum of two persons.

Storage

Dry conditions below +45ºC. Store indoors or under cover on pallets. Do not double stack pallets.

Technical Services

For assistance with working drawings for projects and additional technical advice, please contact GCP Applied technologies.

gcpat.com.cn |详询技术细节,请电邮至: asia.enq@gcpat.com

Australia +1800 334 444 New Zealand +0800 552 235 China Mainland +86 21 3158 2888 Hong Kong +852 2675 7898 Indonesia +62 21 893 4260 Japan +81 3 5226 0231 Korea +82 32 820 0800 Malaysia +60 3 9074 6133 Philippines +632 236 6820 Singapore +65 6265 3033 Thailand +66 2 030 9700 Vietnam +84 28 3710 61688

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

GCP Applied Technologies, PV, Bituthene, Betec and Hydroduct are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies, Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2018 GCP Applied Technologies, Inc. All rights reserved.

GCP Applied Technologies Inc., 62 Whittemore Avenue, Cambridge, MA 02140, USA

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 450, Alpharetta, GA 30009, USA

北京市大兴区亦庄经济技术开发区凉水河二街8号大族企业湾6号楼1层102单元

本文档仅在以下所述的最后更新日期时有效,仅适用于中国境内。 请务必参阅下面URL中的当前可用信息,以便在使用时提供最新的产品信息,这一点非常重要。 gcpat.com.cn也提供其他文献,如承包商手册,技术公告,详细图纸和详细建议以及其他相关文件。 不能依赖其他网站上的信息,因为它们可能不是最新的或适用于您所在地区的条件,我们不对其内容承担任何责任。 如果有任何冲突或需要更多信息,请联系基仕伯客户服务。

Last Updated: 2025-05-15

https://gcpat.com.cn/zh-cn/solutions/products/pv-100-en